Add to Cart

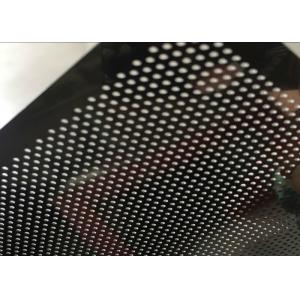

Customized Photo Etching mesh Etched Screen Mesh Filter Grid

Product introduction

| Material | Common material:304/316/430 stainless steel,Special material can be customized. |

| Thickness | 0.05-1mm |

| Hole size |

0.02-0.1mm thick, T=+/-0.02mm 0.1-0.25mm thick, T=+/-0.03mm-+/-0.05mm 0.5-1.0mm thick, T=+/-0.1mm Smallest hole size are as same as material thickness. |

| Technique | Etching/Etched. |

| Shape | round or as your require |

| Technique | Wrapped edge, Spot welded wrapped edge, punching disc and etching etc |

| Feature |

1, consistent cross-sectional thickness 2, accurate aperture shapes / sizes 3, Flexible opening area 4, Special features and differing aperture shapes 5, Burr and stress free and no sharp edge meshes 6, Various material options |

| Application | Widely used in Medical implants, Particle separation, Smoke detectors, High-end automotive interiors, Fuel filtration amd so on. |

Photo etching is used extensively in manufacturing custom meshes, filters and sieves as unlike conventional machining technologies the process offers unlimited complexity – you only pay for the first hole.

Manufactured in a single piece, photo etched meshes are slimmer, cleaner and have greater integrity, making them more robust during handling. Where punch-perforated sheets are prone to distortion, photo etched mesh is burr and stress-free, with zero material degradation.

FAQ: Photo Etching Perforated Metal

Q: What are the limitations for etched screens?

A: The minimum hole size needs to be, preferably, 120% of the metal thickness and the minimum ligature between holes is not less than the metal thickness and never less than .005 inches.

Q: What is the largest screen you can make?

A: Our equipment can process screens up to 24” x 60”

Q: What are the thinnest and thickest materials you can process?

A: .001 inches in most alloys and up to .080 inches in aluminum.

Q: How much do etched screens cost?

A: For common alloys (stainless, copper, brass, aluminum) between .010 and .020 thick, you can expect costs between .20 and .30 per square inch, assuming 120% minimum hole size.

Q: How much does tooling cost?

A: For screens up to 24” x 24”, generally, $285.00

Q: Do you have any standard screens?

A: No. Everything is made to customer specifications.

Q: Do the holes have to be round?

A: No. The holes can be virtually any shape and they don’t have to be the same shape. Any collection of shapes can be made. The caveat is that the minimum radius is equal to the material thickness and the 120% rule applies to the narrowest area of an opening.

Q: Can screens have solid borders?

A: Yes.

Any need and questions, pls feel free to contact with me soon!